Petrozavodskmash has begun to ship reactor coolant pump housings for Tianwan NPS

Petrozavodskmash plant (a member of machine engineering division of Rosatom State Corporation, and regional division of the Russian Engineering Union (SoyuzMash) has begun to ship reactor coolant pump housings for Tianwan NPS, Unit 7 being constructed in the People’s Republic of China.

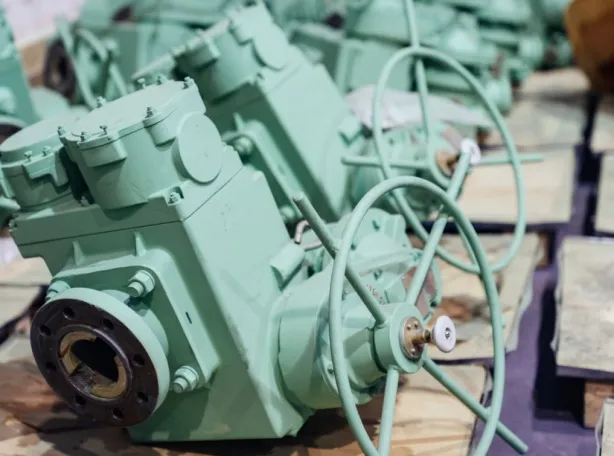

An RCP housing is a safety class I item. At a nuclear power station, the reactor coolant pump is to ensure coolant circulation within the primary circuit. It operates under a pressure of around 16 MPa and at a temperature of about 300°C. One housing is over 31 t in weight, 3.5 m in height and over 3 m in width. As assembled with a spacer, the weight of the item reaches 48 tonnes.

In the course of manufacture, the RCP housings are subjected to all necessary kinds of inspection, particularly radiography, and a series of tests, of which hydraulic tests under overpressure (24.5 MPa) are of key importance. Upon approval as a result of all the inspections, the equipment is ready for shipment after being paint coated and preserved.

Petrozavodskmash has shipped the first RCP housing for Tianwan NPS. In total, the scope of delivery comprises four RCP housings and spacers.

Tianwan NPS is located in China. The third stage of the power station is constructed under the NPP-2006 concept and complies with IAEA’s current safety requirements.

Russia has been consistently developing international trade and economic relations. Despite external constraints, the domestic economy is augmenting its export potential and supplying goods, services, and raw materials all across the world.