Welding production

Welding production of Atommash is equipped with modern high-precision welding facilities. The work process is fully automated, which ensures consistent production of large volumes of products and high quality of welded joints.

Equipment

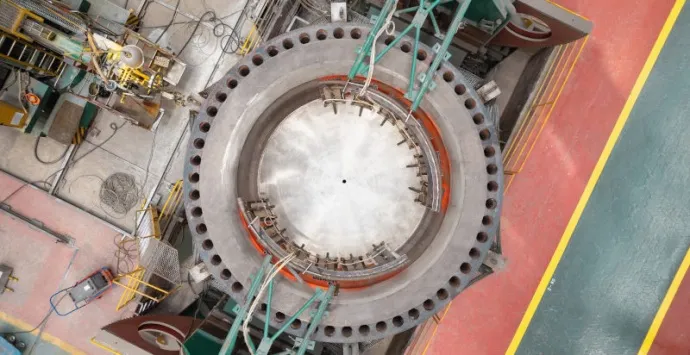

Plant for inside overlay welding of heads, flanges and ellipsoids

| Description |

Automated plant is used for welding and overlay welding of heads, flanges and ellipsoids in the manufacture of

VVER reactors. Weld overlay can be made by submerged-arc welding with a strip or wire. The Plant is able to provide overlay welding of corrosion-resistant cladding layer. |

| Main characteristics |

Maximum product diameter: up to 6 500 mm

Wall thickness: 100 – 400 mm Load capacity of the manipulator: up to 350 t |

Plant for welding of circumferential welds of half-vessels

| Description | The Plant is used for automated multilayer welding of the sphere and flange of the upper unit top head, as well as circumferential welds of half-vessels of the reactor, steam generator, and ECCS accumulator.

|

| Main characteristics | Product diameter: 3 000 – 6 500 mm Product length: 3 000 – 8 000 mm Wall thickness: 100 – 400 mm Maximum product weight: up to 400 t Heating temperature: 100 - 350 °С

|

Plant for inside overlay welding of shells and vessels

| Description | The automated plant is used for welding

and overlay welding of shells and vessels of VVER reactors. The weld overlay

is made by submerged-arc welding. The Plant is able to overlay a cladding

layer up to 8 mm thick. |

| Main characteristics |

Maximum product diameter: up to 6 500 mm

Wall thickness: 100 – 400 mm Load capacity of the manipulator: up to 350 t

|

Production Capabilities

01

More than 20 units of unique high-precision equipment from leading world brands

02

Full automation of the welding process with the ability to switch between modes

03

Application of various welding engineering processes: ESHS, ASF, ESHN

High-tech equipment allows us to produce products of various shapes and sizes. The welding production capacities are involved in the manufacture of tanks and vessels, heat-exchange equipment, machine-building structures and other types of products.